All About Flooring!

Are you wanting to change up your floorboards? Why not take a look at our range of fantastic flooring products that was launched back in 2018. We have three flooring products that are easy to use whether you're experienced or brand new to DIY! These products are: Pre-Conditioner, Floor Dye and Floor Fast Varnish. At first, our floor dyes started off with 10 colours, but it has since welcomed our Driftwood Grey and Driftwood Brown into the mix.

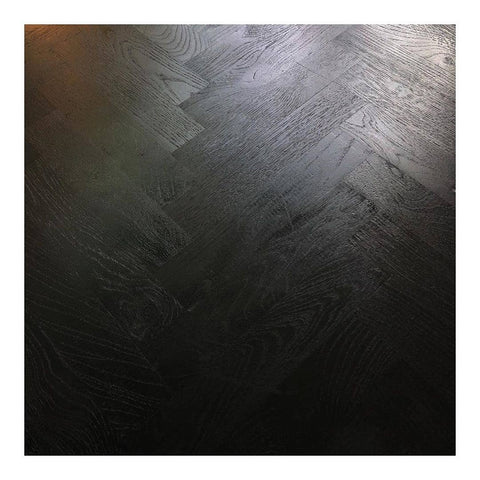

Driftwood Grey and 2 coats of Satin Varnish

Preparation

Preparation is key! In order for your floorboards to accept our dye and provide the best possible finish, whether they are old or new, it is important that you prepare your floorboards correctly.

Old floorboards! These should be sanded as evenly as possible, including around the edges. Always aim to sand along the grain. You will probably need to begin with a coarse abrasive (60 Grit). This will create scratches on the wood, so you will need to work towards a final sanding with 120 Grit to achieve a smooth finish.

New floorboards! Your new wood may appear clean, fresh and ready to be dyed. However, it will accept the dye better if you sand it in the same manner as older floorboards. It isn’t always obvious but if you just dye the new un-sanded wood then any machining marks might become apparent as faint stripes across the width of the board. This problem is easily overcome by thoroughly sanding as above. It’s often easier to pre-sand new floorboards before laying. If you lightly dampen the wood first with water and allow it to dry this will raise the grain a little and make it easier to sand. This will also help prevent the grain being raised when you apply the dye.

What’s next? After preparing your floorboards you now need to decide whether you’d like a clearer, lighter, more ‘modern’ look or a ‘rustic, aged’ effect. If you prefer a more modern look then you could apply our Pre-Conditioner before applying the dye. However, you do not need to apply the Pre-Conditioner if you do not want to!

Pre-Conditioner

Our Pre-Conditioner is a water based formula intended for use before applying our floor dye where a clearer, lighter, more ‘modern’ look is desired. It will penetrate bare pine and porous hardwoods, partially sealing the grain allowing the dye to colour the wood more evenly. It is quick drying and easy to apply!

We’d recommend it for use with the following traditional colours: Light Stripped Pine, English Walnut, Fumed Oak, Anglian Oak, Gilded Oak, Sienna Mahogany, Mellowed Pine and Modern Oak.

We wouldn’t recommend it for use with our African Ebony, Seawashed White, Driftwood Grey or Driftwood Brown.

Next up is our Floor Dyes!

Our unique range of floor dyes has been developed using decades of experience and expert knowledge, for use on new or re-sanded floorboards. Our dyes are quick drying, lightfast and have an easy brush clean.

We have 12 colours and these are: African Ebony, Anglian Oak, English Walnut, Fumed Oak, Gilded Oak, Light Stripped Pine, Mellowed Pine, Modern Oak, Seawashed White, Sienna Mahogany, Driftwood Grey and Driftwood Brown.

Our Light Stripped Pine will create that beautiful 'old stripped pine' look for your project, whilst English Walnut, Fumed Oak, Anglian Oak, Gilded Oak, Modern Oak and Sienna Mahogany will create a beautiful, authentic hardwood colour and Mellowed Pine will create a beautiful, old dark pine look.

Driftwood Grey and Driftwood Brown can be used on smooth planed, rough sawn or pressure treated timber, both indoors and outdoors*. The more textured or grainy the surface, the greater the effect. Please take a read of our ‘All About Driftwood Grey’ blog if you’d like to read more about these dyes.

Looking for black or white? Our African Ebony can be applied as a light wash or easily build up to a dense blackness with further coats whilst Seawashed White can be applied as a light wash or easily build up to a strong 'chalky' white with further coats.

The dye can then be completed by applying our quick drying Floor Fast Varnish for a very tough, hard-wearing finish. Up next!

Floor Fast Varnish

Now let’s add further protection! To finish off, we have our Floor Fast Varnish. This comes in three finishes: Matt, Satin and Gloss. The sheen % of these are: 10% Matt, 30% Satin and 70% Gloss.

Our Floor Fast Varnish is a very tough, hardwearing finish which is formulated to protect new or re-sanded soft or hardwood floors from knocks, scratches and spillages. This is a quick drying, low odour, non-yellowing varnish, ideal for protecting soft and hardwood floors and many other areas that require a durable surface. It can be applied to most types of wood and manufactured boards, such as plywood and MDF. It can also be used on concrete and unsealed terracotta. The varnish will be touch dry in approximately twenty minutes and can usually be recoated after two-three hours in suitable conditions. Therefore, a floor can be walked on wearing soft footwear within the day. The varnish will need time to cure and harden. So, the longer you can leave the floor, the better. If you are applying the varnish over our dyes then it should be possible to both dye the wood and apply two full coats of varnish in a day, after an early start!

Our Floor Fast Varnish is for indoor use only. If you are looking to protect outdoor decking then look no further than our Decking Oil Plus!

African Ebony and Floor Fast Matt Varnish

Helpful Information About Our Varnish!

- It is a water based varnish that provides excellent protection and is easy to apply.

- The varnish is highly resistant to water providing the moisture does not get underneath, usually within the joints if the floor is tongue and groove.

- Our varnish works well over milk, mineral and chalk paint.

- The varnish should be used at room temperature, or certainly no less than 10 degrees celsius. Our varnish relies on the water evaporating which will not happen if it is too cold, leading to cracking in the finish.

- Our varnish can be applied via a spray gun but we recommend adding a little cold water into the spray gun for the first coat, up to 20%.

- Our varnish is non-yellowing as it is water based and does not contain natural resins which causes the yellowing in solvent based varnishes.

- Our varnish can also be used over solvent based stains and paints.

- If you are applying our varnish onto a black/darker coloured surface.. then please note that we’d recommend either the satin or gloss varnish as our matt varnish may ‘cloud’ over black/darker coloured dyes, stains and paints. However, if you do prefer a matt finish then please produce a tester piece first, to ensure you get the finish that you require. We always recommend doing this!

Please see a couple of photos below of customers that have used our flooring products to complete their flooring projects!

African Ebony and Danish Oil

Seawashed White

English Walnut

Thank you for taking your time to read All About Flooring! If you need more advice about flooring then please take a read of our Breathe New Life Into Your Floorboards blog or get in touch here.

Please don’t forget to use #Littlefairs if you have used any of our flooring products! We love seeing your photos! You can take a look at our Flooring Products here.

*Please note: We do not recommend applying Driftwood Grey or Driftwood Brown to decking, or in a place subject to standing water, as the ingredients can often prevent the dye and oil from penetrating the wood thoroughly, having an adverse effect on the protective properties of the products.