Interior Floor Dye

| Drying Time |

Touch dry in approximately 2-3 hours. However, the Driftwood colours will take a little longer, approximately 4 hours - overnight if possible. Please note: this is an approximate drying time. There could be a number of factors that may affect this. |

| Coverage |

Approx. coverage of 10-12m² per litre, for one liberal coat. |

Developed using decades of experience and expert knowledge Littlefair's bring you a unique Water Based Interior Floor Dye for use on new or re-sanded floorboards.

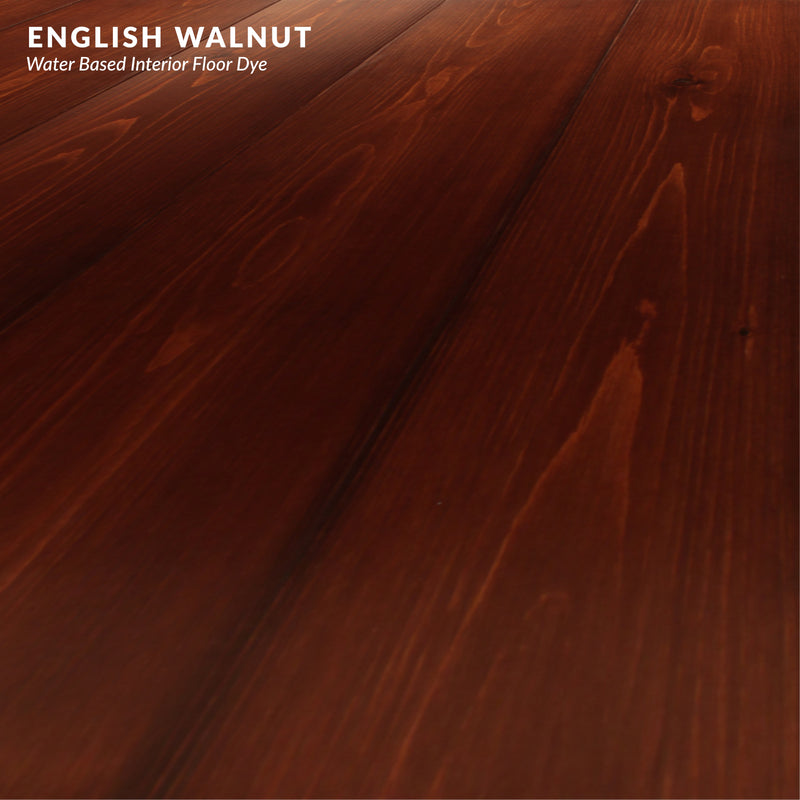

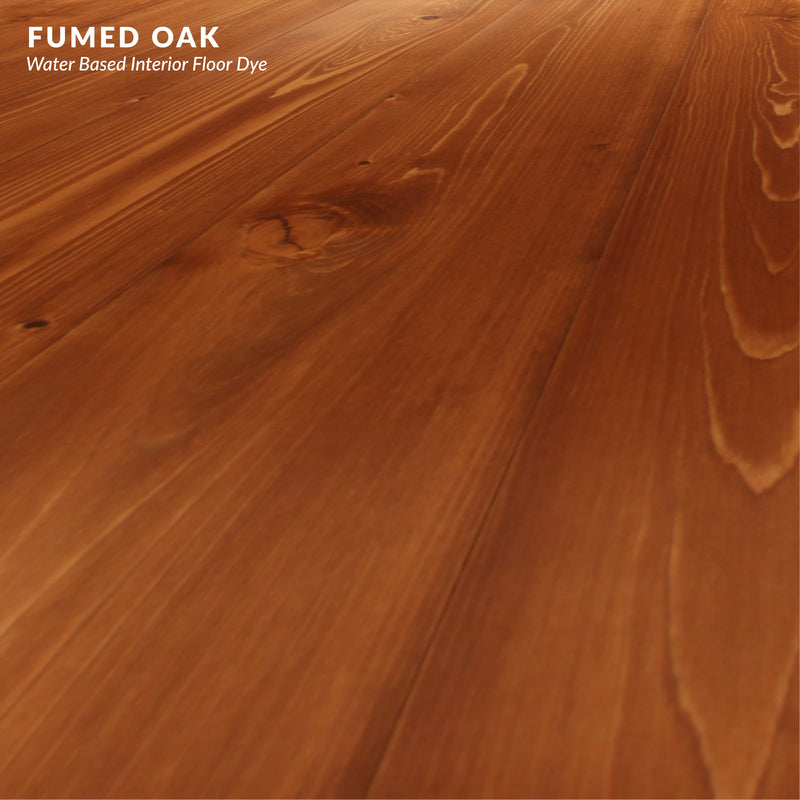

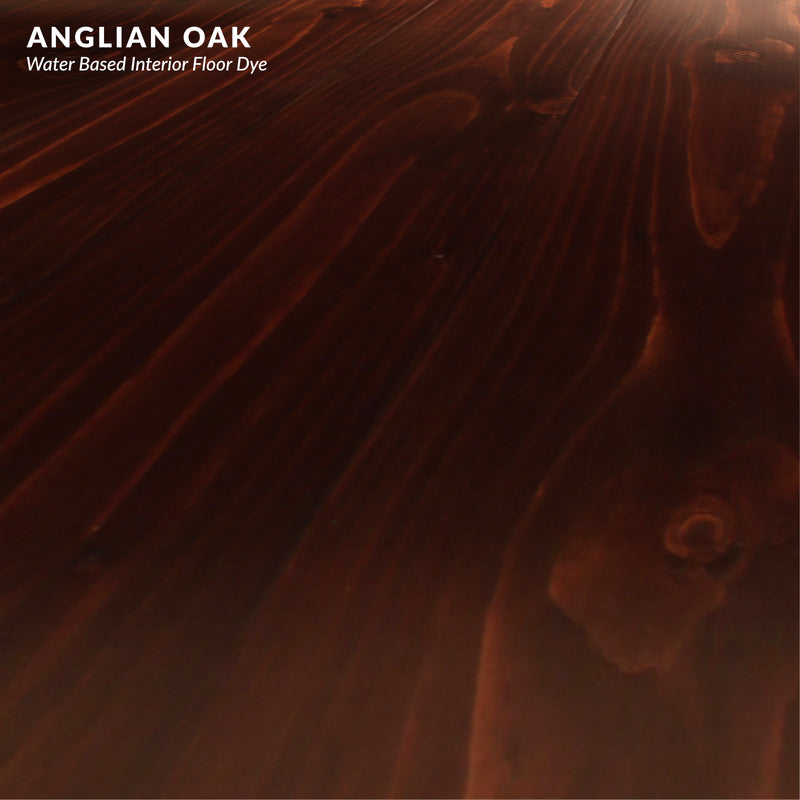

Our Light Stripped Pine floor dye will create that beautiful 'old stripped pine' look for your project, whilst English Walnut, Fumed Oak, Anglian Oak, Gilded Oak, Modern Oak and Sienna Mahogany floor dye will create a beautiful, authentic hardwood colour and Mellowed Pine will create a beautiful, old dark pine look.

Driftwood Grey and Driftwood Brown can be used on smooth planed, rough sawn or pressure treated timber, both indoors and on external wood. The more textured or grainy the surface, the greater the effect.

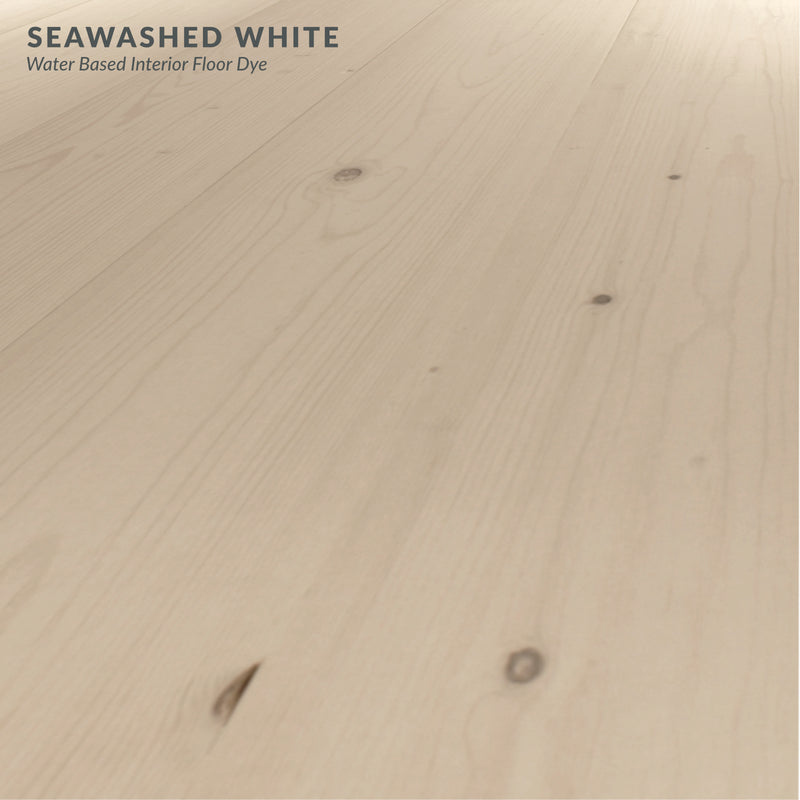

Looking for black or white? Our African Ebony floor dye can be applied as a light wash or easily build up to a dense blackness with further coats whilst Seawashed White can be applied as a light wash or easily build up to a strong 'chalky' white with further coats.

Our Water Based Floor Dye is quick drying and lightfast. Due to it being water based your brush will be very easy to clean and with very low VOCs there will be hardly any odour.

Should you wish to create a more 'modern' look, try using our Water Based Floor Dye Pre-Conditioner before applying our dye. This will create a clearer and lighter finish. Please note, the Pre-Conditioner is best used with our traditional colours - we wouldn't recommend using it with African Ebony, Seawashed White, Driftwood Grey or Driftwood Brown.

To help you achieve the perfect finish you're looking for we offer 15ml Tester Pots of all our 12 floor dye colours.

|

Colour Reproduction

Please note that the example images shown here have been finished with our Water Based Floor Fast Satin Varnish. We endeavour to reproduce our colours and finishes as accurately as possible - both online and in print. However there are a range of factors to consider when comparing our samples to your chosen project: the type and condition of the surface itself may produce a slightly different appearance of the finished colour. Please bear in mind the shape, size and lighting conditions. |

|

Please note: Our Water Based Wood Dyes have a matt appearance when dry and come to life when finished with Littlefair’s Wood Finishing Products. We recommend finishing your project to provide the dyed wood with extra protection. We do not recommend finishing African Ebony with matt varnish as this can create a cloudy appearance. |